We turn complexity into clarity – and automation into impact.

Scale smarter, faster, safer

Solutions for growth companies

Growth companies face the challenge of scaling production quickly without losing control, quality or flexibility. Whether you are a scale-up in energy technology or a family-owned manufacturer in expansion, we provide modular solutions and long-term expertise that help you scale sustainably from day one.

Scaling challenges for growing manufacturers

Scaling up is about more than speed. Growth companies must move quickly from prototypes to serial production while keeping costs under control and ensuring reliability. At the same time, customers and investors expect sustainable operations from the start.

Typical challenges include:

-

Moving from pilot runs to stable serial production

-

Building modular systems that grow with demand

-

Limited in-house automation and process expertise

-

Balancing speed with quality and compliance

-

Delivering sustainable production in a competitive market

Reducing Footprint From 2000 To 50 m²

Longterm partnership with Hultafors

Replacing Three Workstations With One Flexible Line

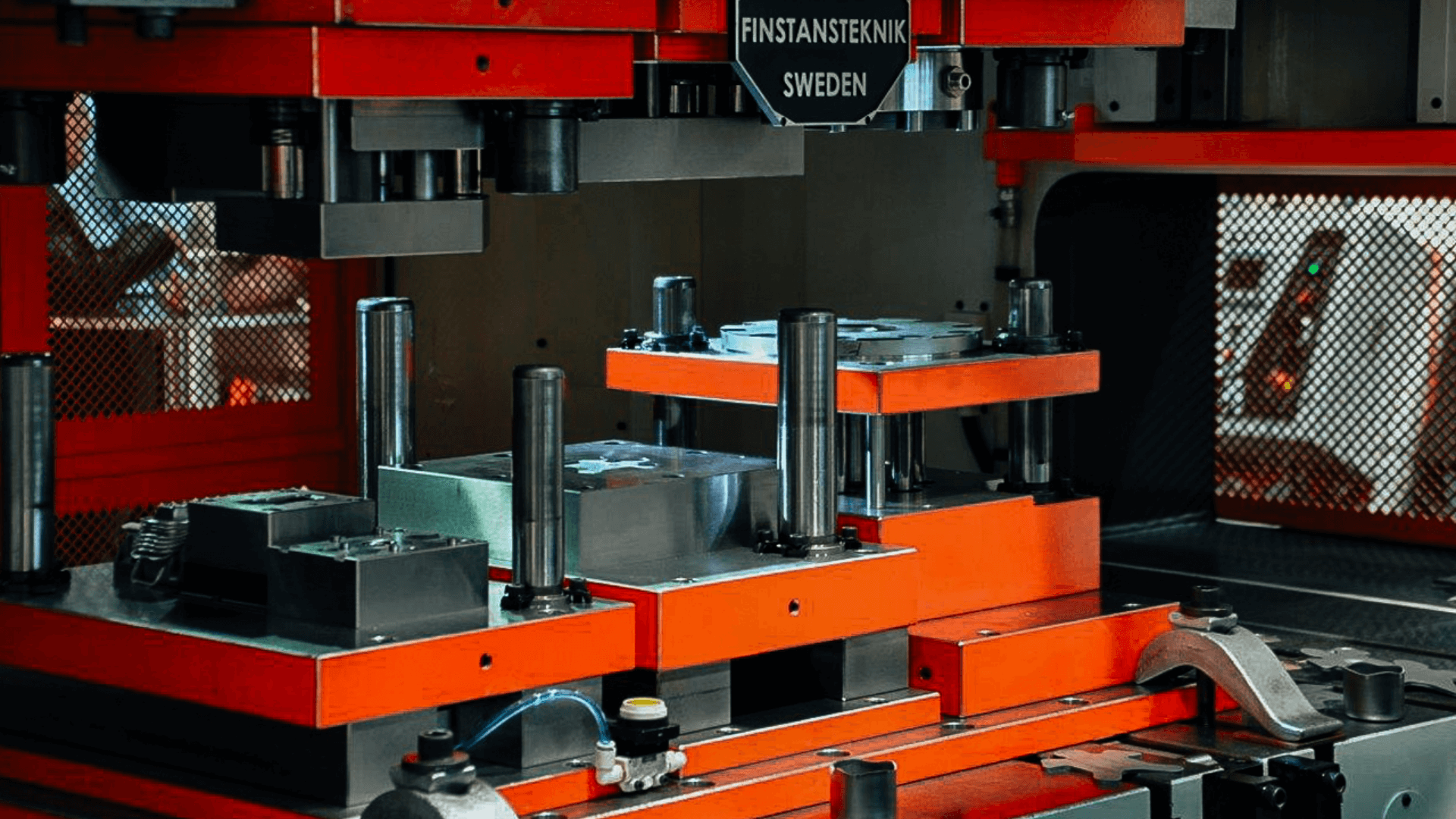

Automation at its finest for Weland

Making Mass Production Possible In Real Time

Our solutions for Scania

How we support scaling companies

We understand the growth journey. Our role is not only to provide machines, but to act as a partner that ensures your production grows safely with your ambitions.

With Finstansteknik you get:

-

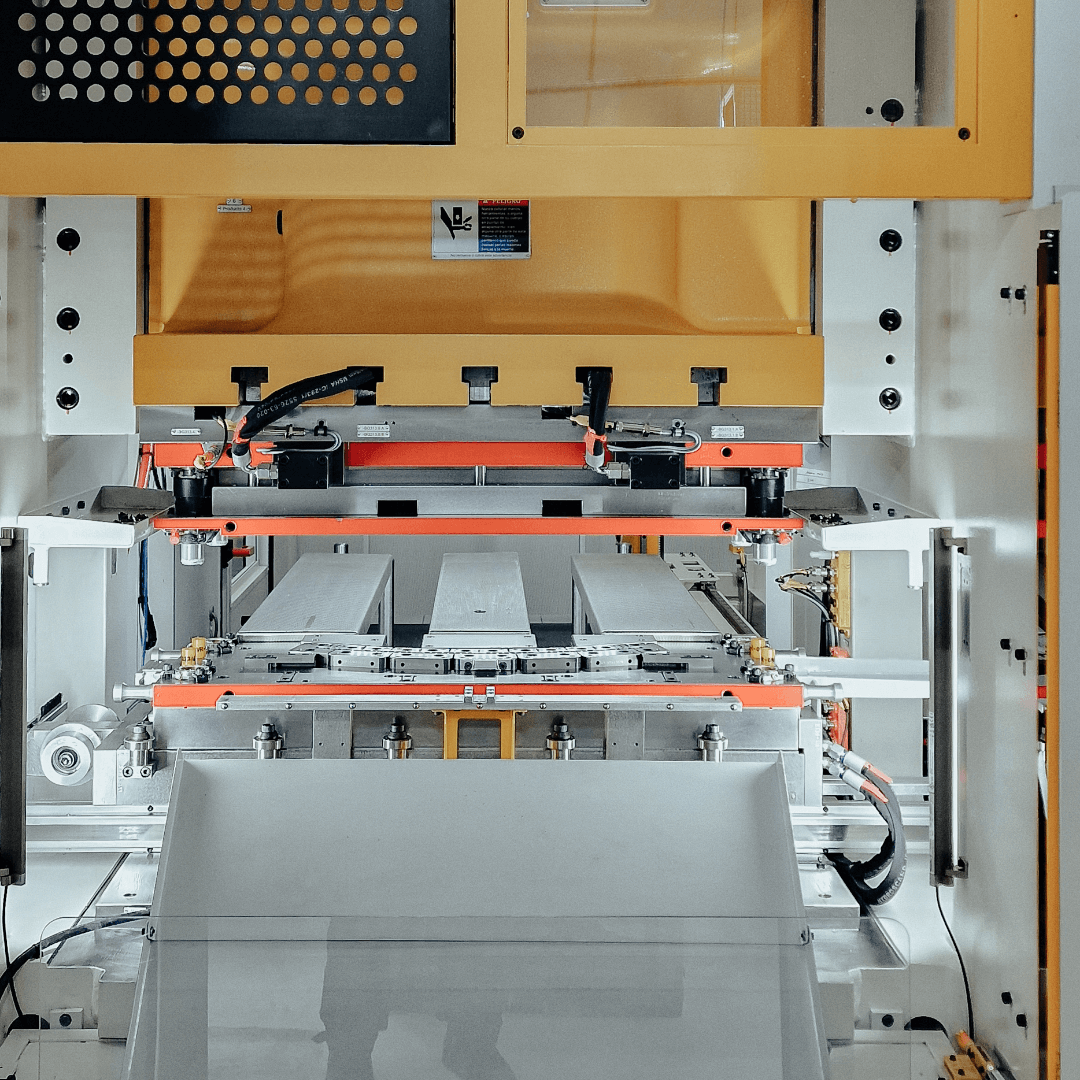

Modular automation – flexible systems that expand step by step

-

Rapid prototyping – faster validation of products and processes

-

End-to-end delivery – from concept and design to installation and support

-

Sustainability built-in – reduced waste, lower energy use and long-lasting results

-

Independent guidance – advice based on your needs, not a fixed product catalogue

Practical applications for growth companies

Our solutions take many forms depending on your business. For some, it starts with a prototype or a small automation cell. For others, it means building complete lines ready for international expansion.

Examples include:

-

Prototyping services that shorten development cycles

-

Automation cells that scale with increased demand

-

Turnkey projects delivering ready-to-run production lines

-

Consultation to complement lean internal engineering teams

“We didn’t need a supplier. We needed someone who could help us figure it out – and build it.”

N N

Weland

Our Process – Simple, Structured And Proven

You Reach Out

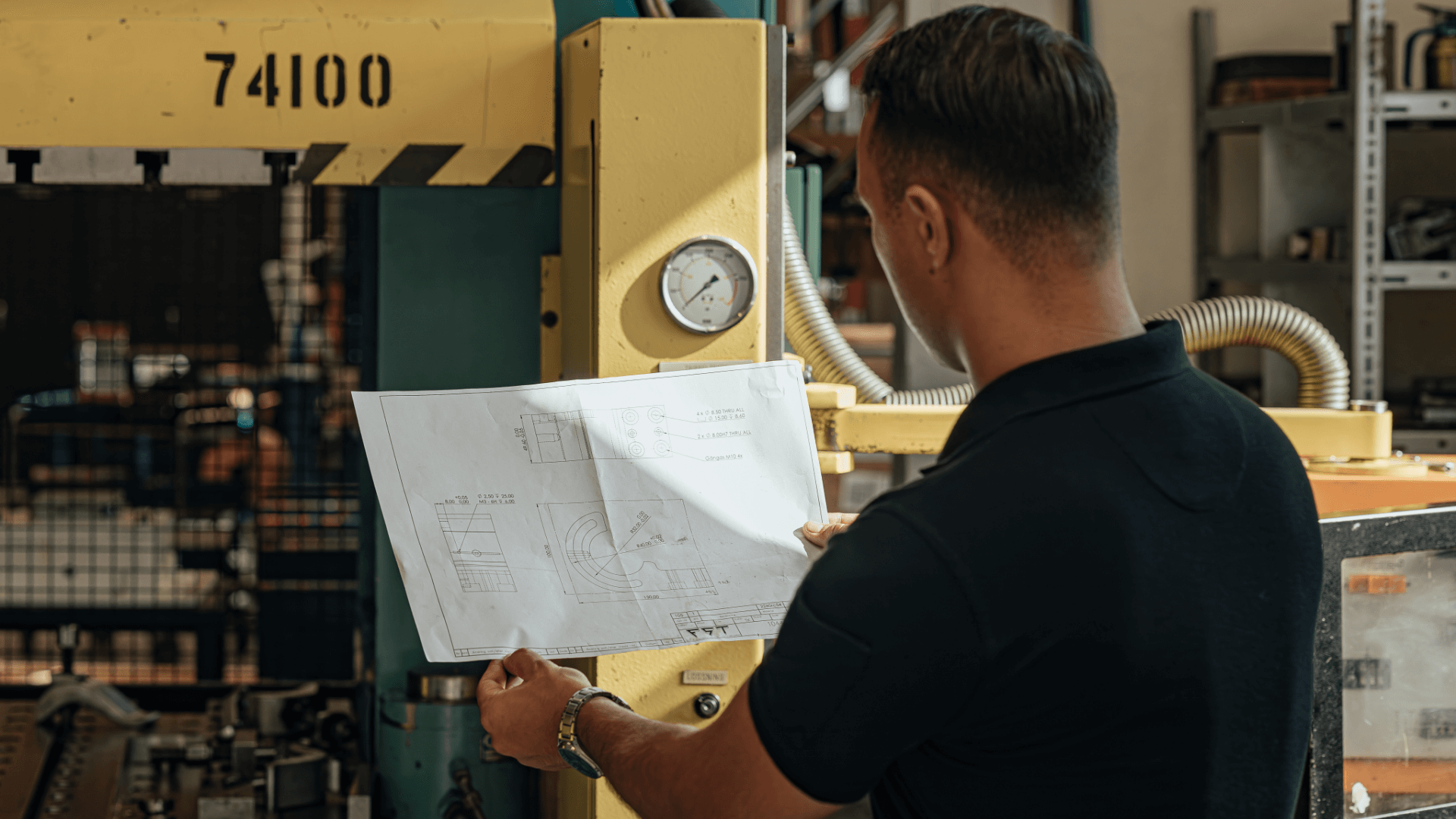

Book a free consultation or send us your drawing. We start by clarifying your challenge – fast and straightforward.

We Listen And Assess

Our engineers review your needs and identify bottlenecks, risks and opportunities. You get insights you can act on.

We Propose A Solution

We create a proposal with clear scope, cost and timeline – not just a quote.

You Decide

Togheter we choose the solution that fits your production goals. We deliver, integrate and support you all the way.

We Deliver

Our team handles everything from production to delivery, with updates along the way.

We Follow Up

We aim to be your long-term partner and solution-maker. Let's stay in touch.

Ready to scale your production?

Got an idea? A bottleneck? A space constraint? Let’s explore what’s possible – together.