Automotive & Industrial OEMs

Tooling, prototyping and automation systems for high-demand industries.

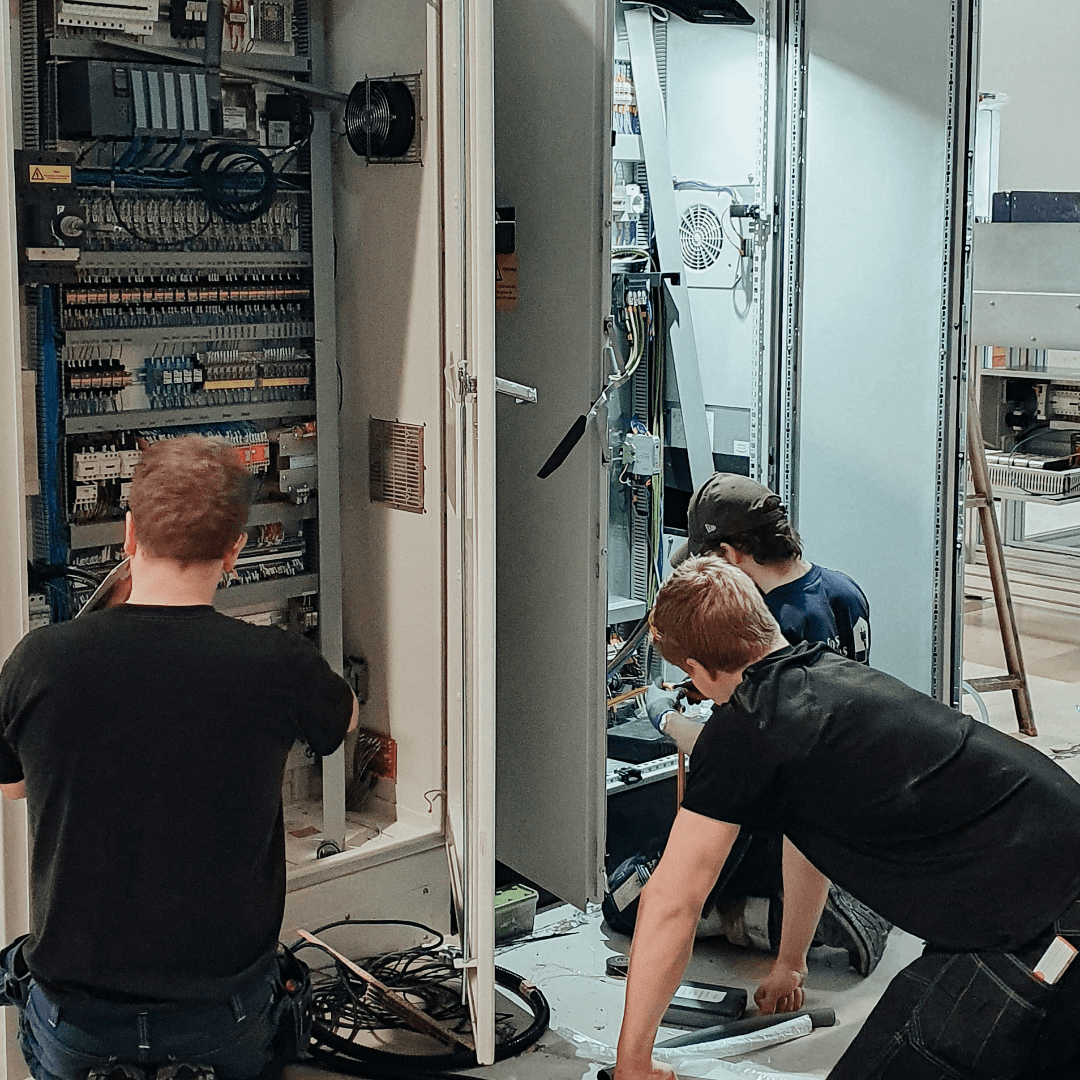

Production Line Relocation

When Every Bolt Counts

Relocating a production line is never just logistics. It’s about preserving process stability, uptime and know-how. At Finstansteknik, we manage the entire move – from planning to reinstallation – so your line restarts as if it never stopped. Our solid expertise in industrial automation and machine manufacturing can also improve the function of your existing machines.

The Challenge:

Moving machines without risking production

Expansions, consolidations or reconfigurations are a natural part of industrial growth. But relocating production equipment always carries risk. Every step – from disassembly to recommissioning – can lead to errors, downtime or compliance issues if not handled properly.

Traditional movers focus only on logistics. What often gets lost is the process knowledge, documentation and calibration that ensures production stability. That’s why production line relocation requires more than transport – it requires technical expertise and structured project management.

Our Solution:

What we bring to the table

Finstansteknik takes full responsibility for relocation projects – securing both the equipment and the production process. With a cross-functional team of technicians, engineers and project managers, we make sure your line is up and running quickly and safely.

Our relocation projects typically include:

- Mapping and documentation of the existing setup

- Disassembly and secure transport

- Reassembly, calibration and functional testing

- CE verification and recommissioning

- Improvement or supplementation of equipment

- Mapping the reliability of mechanical and electrical components

This way, we guarantee that the line doesn’t just move – it starts up again with full performance and compliance intact.

Why Choose Finstansteknik:

Trusted with the most critical moves

Customers choose Finstansteknik because we deliver relocations that are safe, efficient and reliable. We have moved everything from press lines across borders to automation cells between factories and entire workstations during plant modernisations.

Every project is unique, but our principle is the same: careful planning, disciplined execution and full technical responsibility. The result is minimal disruption, preserved documentation and a smooth restart.

Trusted By Global Leaders In Manufacturing

Start planning your line move

We are ready to partner with you. Fill out the form to connect with us, and take the first step towards solving your next challenge.