Automotive & Industrial OEMs

Tooling, prototyping and automation systems for high-demand industries.

Tool & Die Manufacturing

Precision that lasts

We design, manufacture and deliver tooling solutions for demanding production environments. From simple cutting dies to complex progressive tools, every project is engineered for stability, repeatability and long-term performance. With Finstansteknik as your partner, tooling becomes an enabler – not a bottleneck.

The Challenge:

When good enough isn’t good enough

For many manufacturers, tooling is the weakest link in production. A tool that is just slightly off can cause scrap, downtime and poor fit – problems that escalate quickly in high-volume environments.

Most partners only deliver what’s on the drawing. Few take responsibility for the long-term production stability, tolerances and serviceability that actually determine whether a tool will perform thousands of cycles without failure. That’s where Finstansteknik makes the difference.

The result? Constant pressure to improve line efficiency, reduce downtime and scale output without increasing costs. Very few suppliers can support this balancing act with both automation expertise and responsive service – and that is exactly what Finstansteknik delivers.

Our Solution:

What we bring to the table

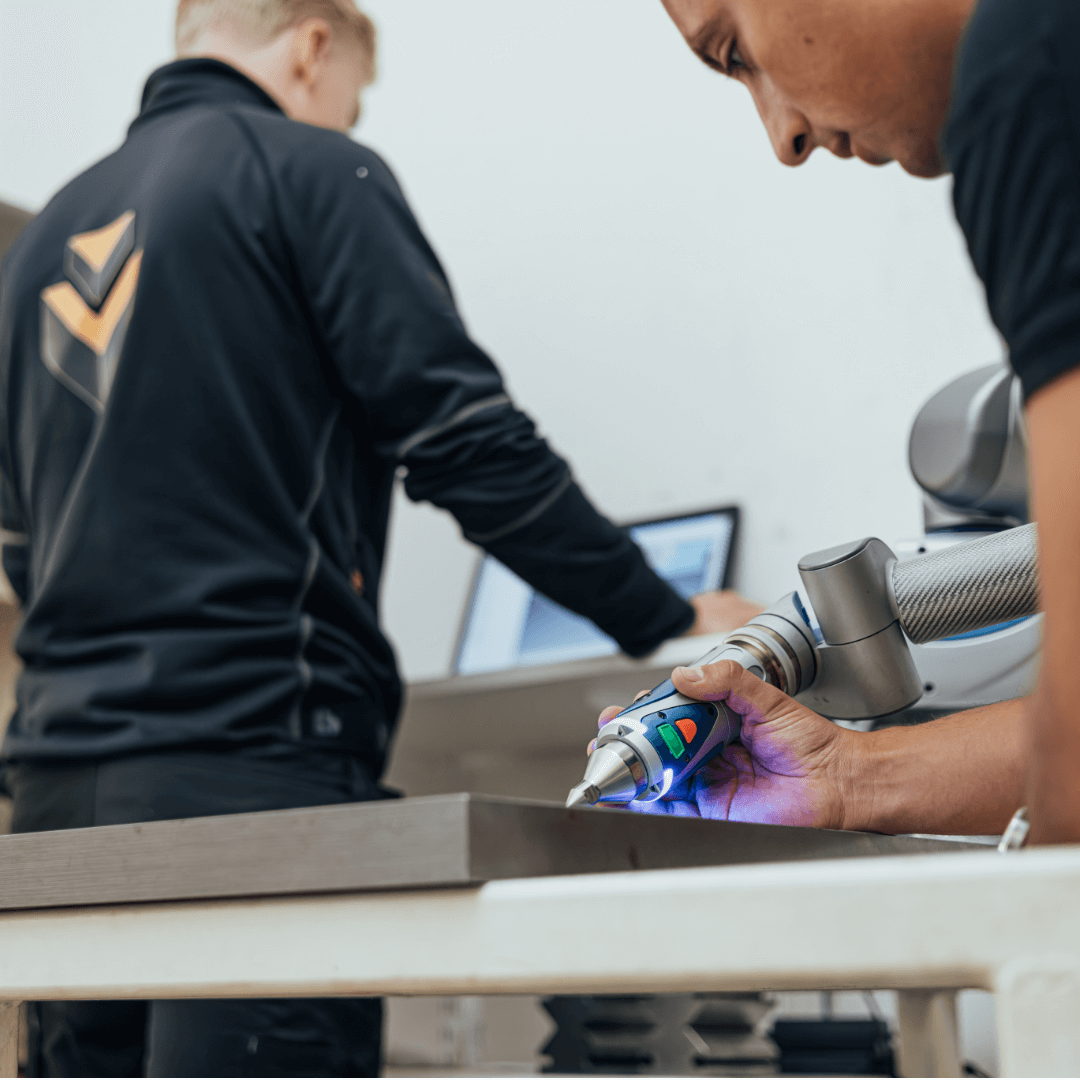

At Finstansteknik, we don’t just “make the tool.” We act as a development partner – analysing requirements, reviewing tolerances and suggesting improvements before production starts. Every delivery is designed not only to meet specifications, but to ensure reliable performance in real-world conditions.

Our tooling projects always include:

- Technical review and design feedback

- In-house tool design and manufacturing

- Assembly, testing and documentation

- Optional support for CE certification and production integration

We combine high-precision machining, grinding and assembly with robust project documentation. Each tool is designed for stability, repeatability and serviceability, ensuring consistent results from first-off tool trials to full-scale production.

And when requirements change? Iterations and modifications are handled smoothly and efficiently, keeping your production on track.

Why Choose Finstansteknik:

Full range of tooling expertise

We manufacture press tools and dies across a wide spectrum of stamping and forming applications. Our expertise spans progressive and transfer dies, deep drawing, fine blanking, press hardening and high-precision tooling. This breadth of capability allows us to recommend the right concept for each project – balancing precision, cost and production stability.

Our tool and die solutions are built not only to perform – but to simplify production. The results are tangible: less variation, smoother setups and fewer unplanned stops. Customers tell us our tools “just work” – and keep working, even after thousands of cycles. That reliability is why so many OEMs and manufacturers choose Finstansteknik as their long-term tooling partner.

Trusted By Global Leaders In Manufacturing

Ready to tackle your next challenge?

We are ready to partner with you. Fill out the form to connect with Nader, and take the first step towards solving your next challenge.